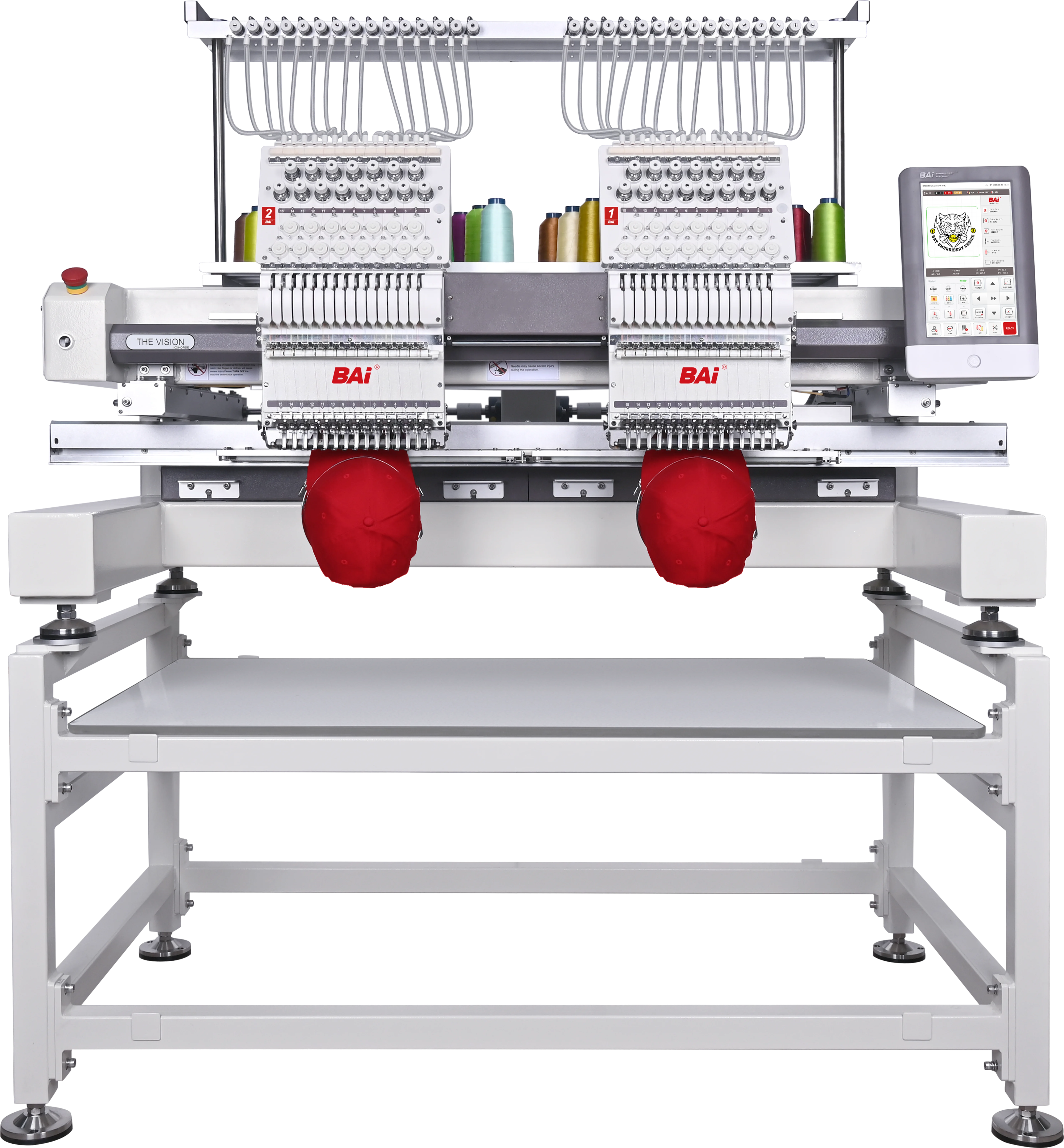

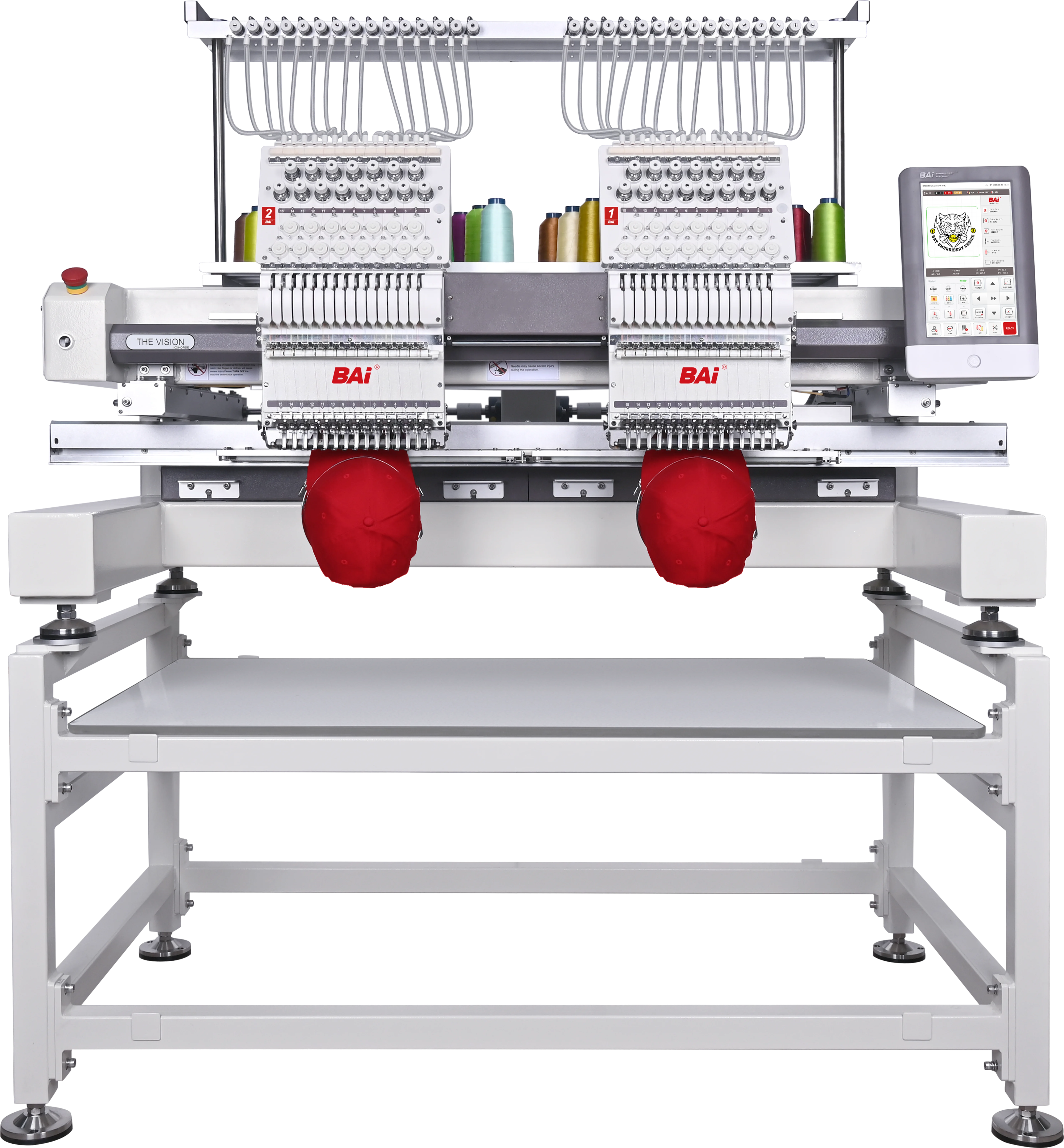

THE VISION-2HEADS

Powerful assistant for business growth

$10,999

More stable,more fast,better help for business growth

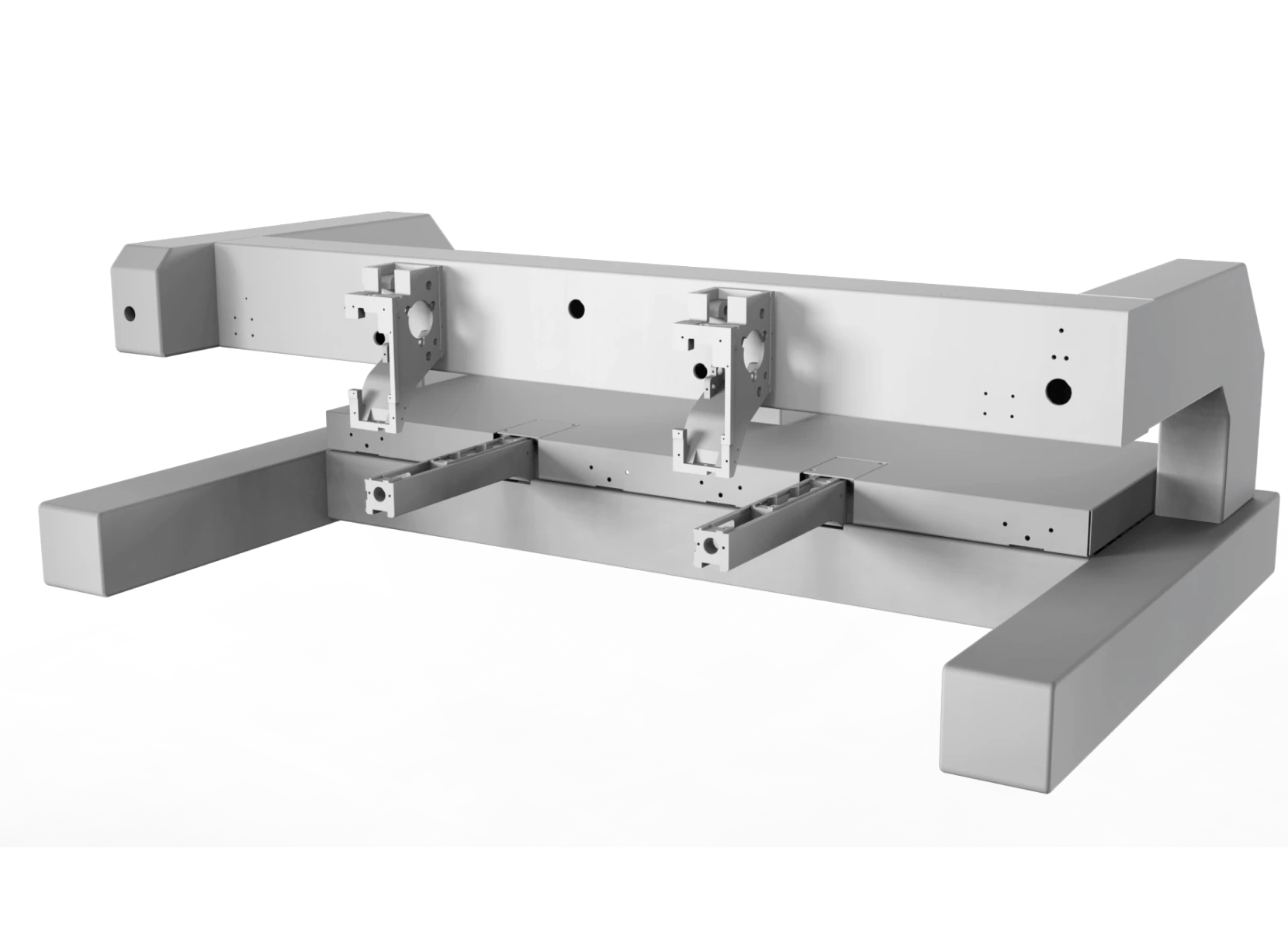

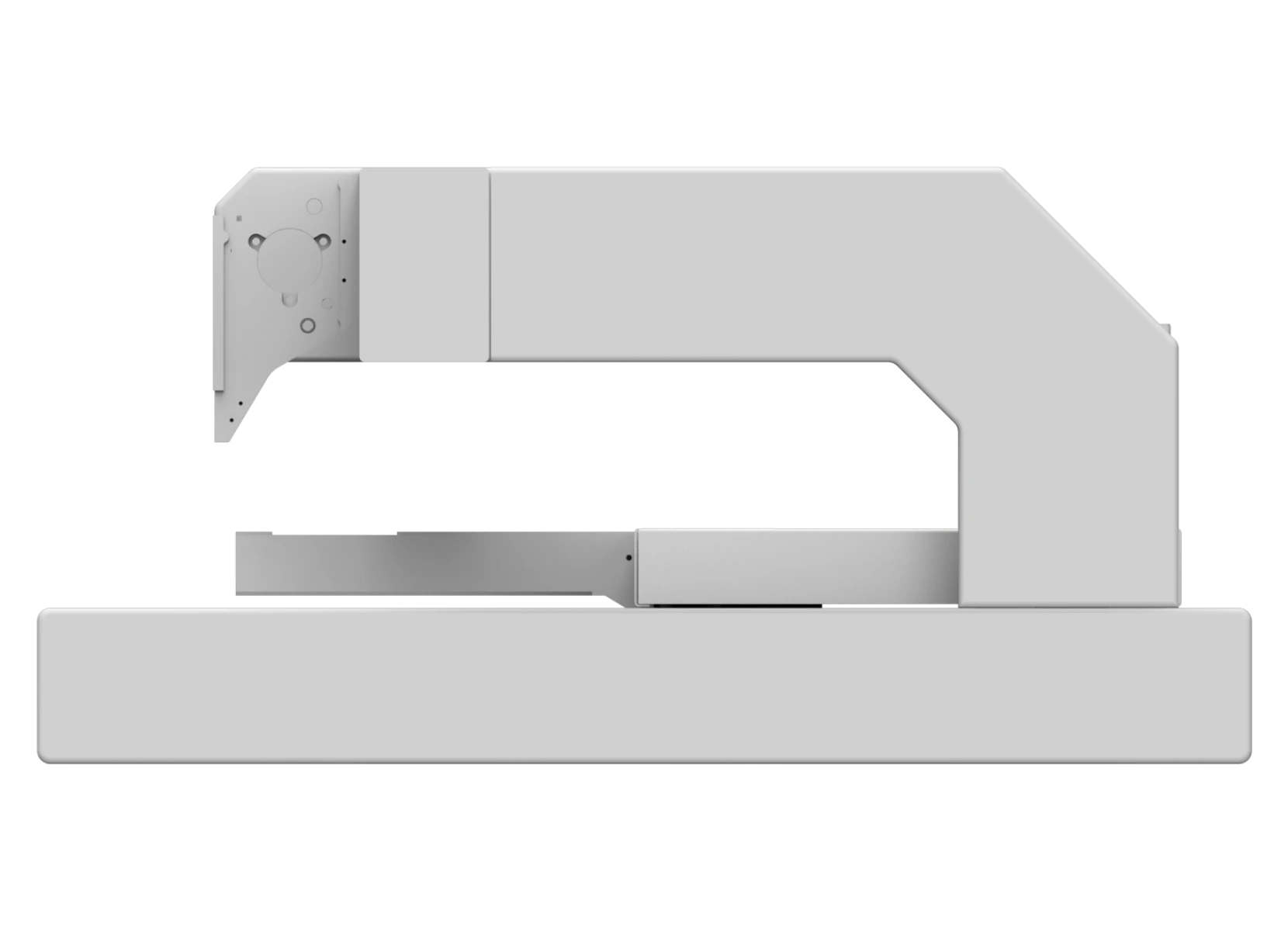

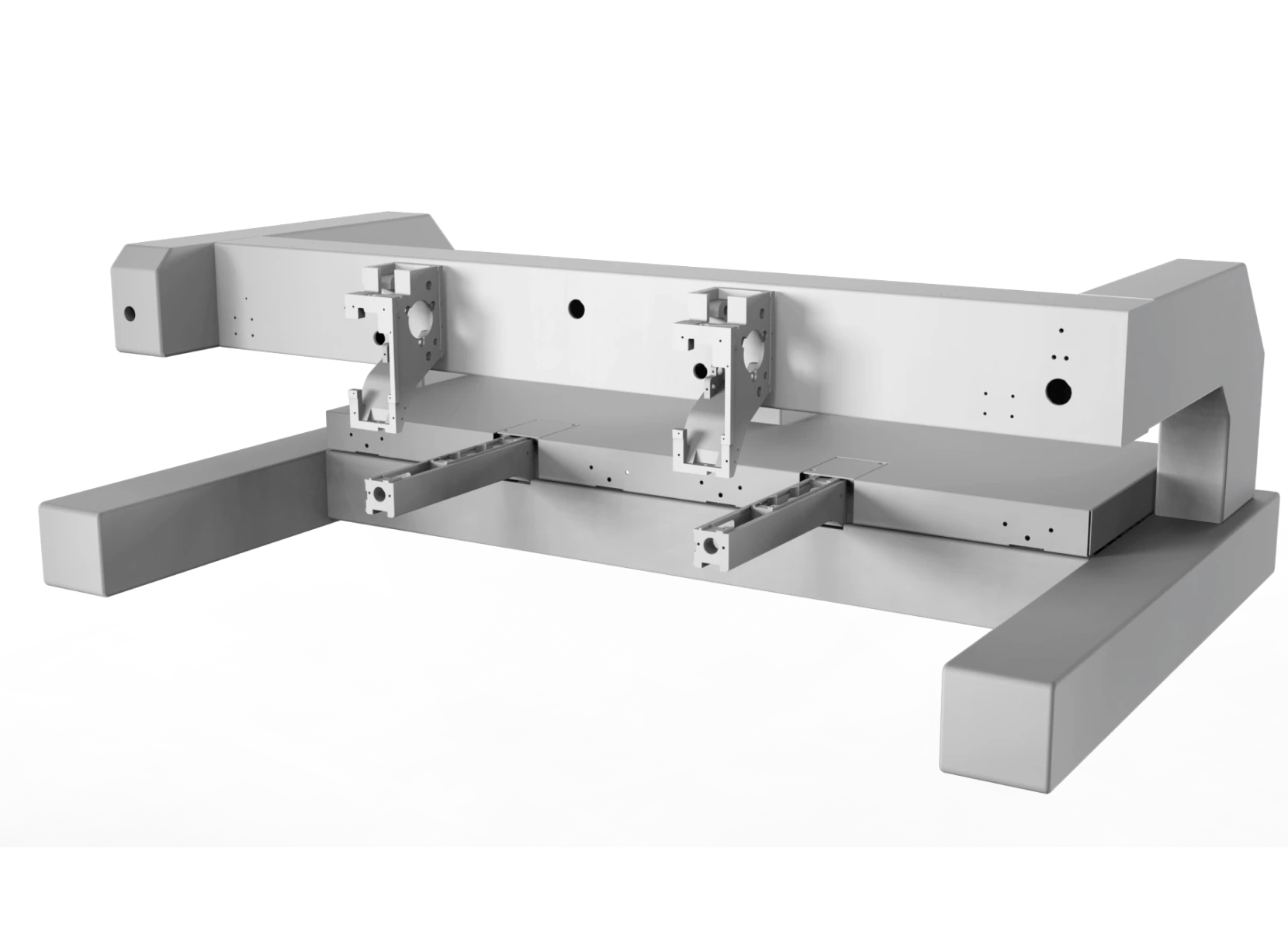

By optimizing the structure and control panel, we have significantly improved the machine's stability and speed. The transmission system ensures smooth operation at high speeds, while the enhanced control panel delivers more precise operation and responsiveness. We also focus on maintenance convenience, allowing users to quickly replace parts, minimize downtime, and improve production efficiency.

More stable for hat embroidery

100% focused on hat embroidery

#Insufficient penetration of structured hats causes needle breakage

Use sharp needles: Choose a 75/11 sharp needle suitable for hard materials.

Enhance machine penetration: Adjust the machine head force or replace with components supporting thick material embroidery.

Upgrade needle bar power system: Enhance the stability and impact force of the needle bar to penetrate thicker hat structures.

Install stronger needle bar springs: Ensure the needle bar operates smoothly under high-pressure conditions.

#Thread breakage on structured hats

Upgrade the rotary hook system: Use a high-speed, low-friction rotary hook to better handle hard material embroidery.

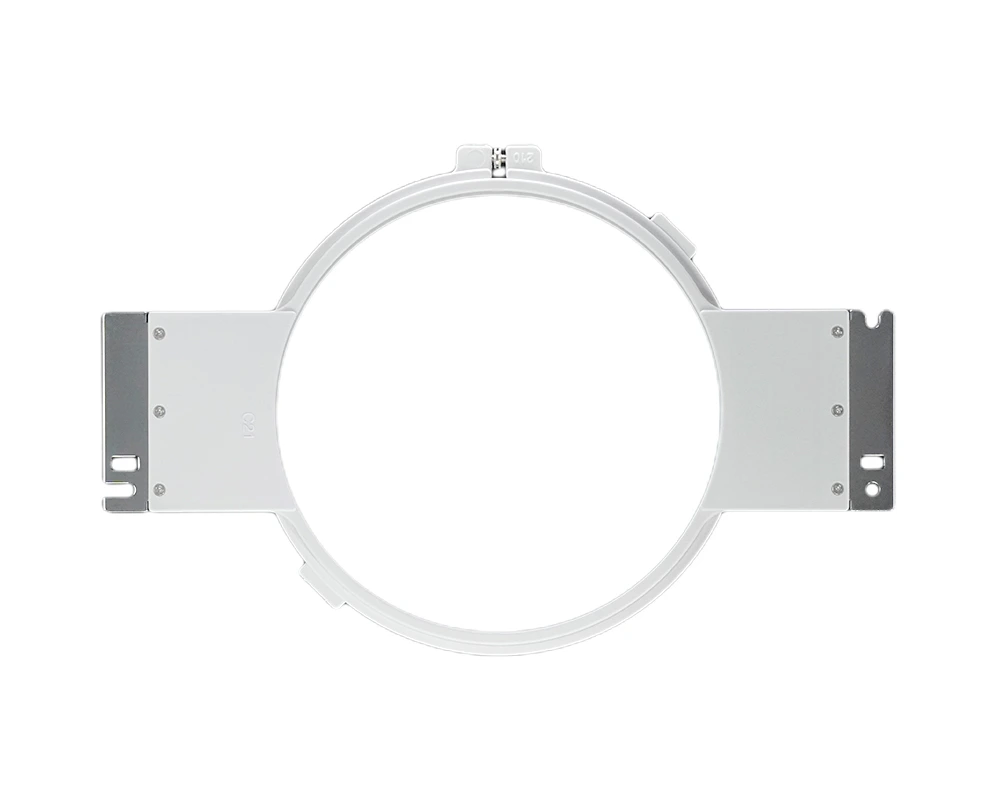

#Side embroidery requires disassembly

One-click hoop selection: Directly select the hat side hoop on the interface; the machine will automatically recognize and adjust without manual disassembly or adjustment.

#Hat embroidery speed is limited to 500-700 SPM with significant deceleration ratio

Add intelligent speed reduction algorithm: The machine dynamically adjusts speed based on hat material and embroidery thread, optimizing path planning and improving efficiency.

Improve data processing speed: Use more advanced motherboards and processing chips to reduce embroidery path delays and errors.

#The hat brim is too far

Optimize machine head design: By improving the machine head design and extending the range of motion, the machine can embroider closer to the hat brim, enhancing accuracy and quality.

#Machine head scratches and damages the hat

Optimize hat drive design: Reduce friction between the clamp and hoop to protect hat materials.

Optimize hoop design: Improve the cap top design to maintain the proper distance between the hat and the machine.

#3D embroidery foam leak and misalignment

Adjust presser foot height: Ensure optimal presser foot positioning to prevent adhesive misalignment.

Built-in 3D embroidery optimization algorithm: Ensure design and machine operation consistency.

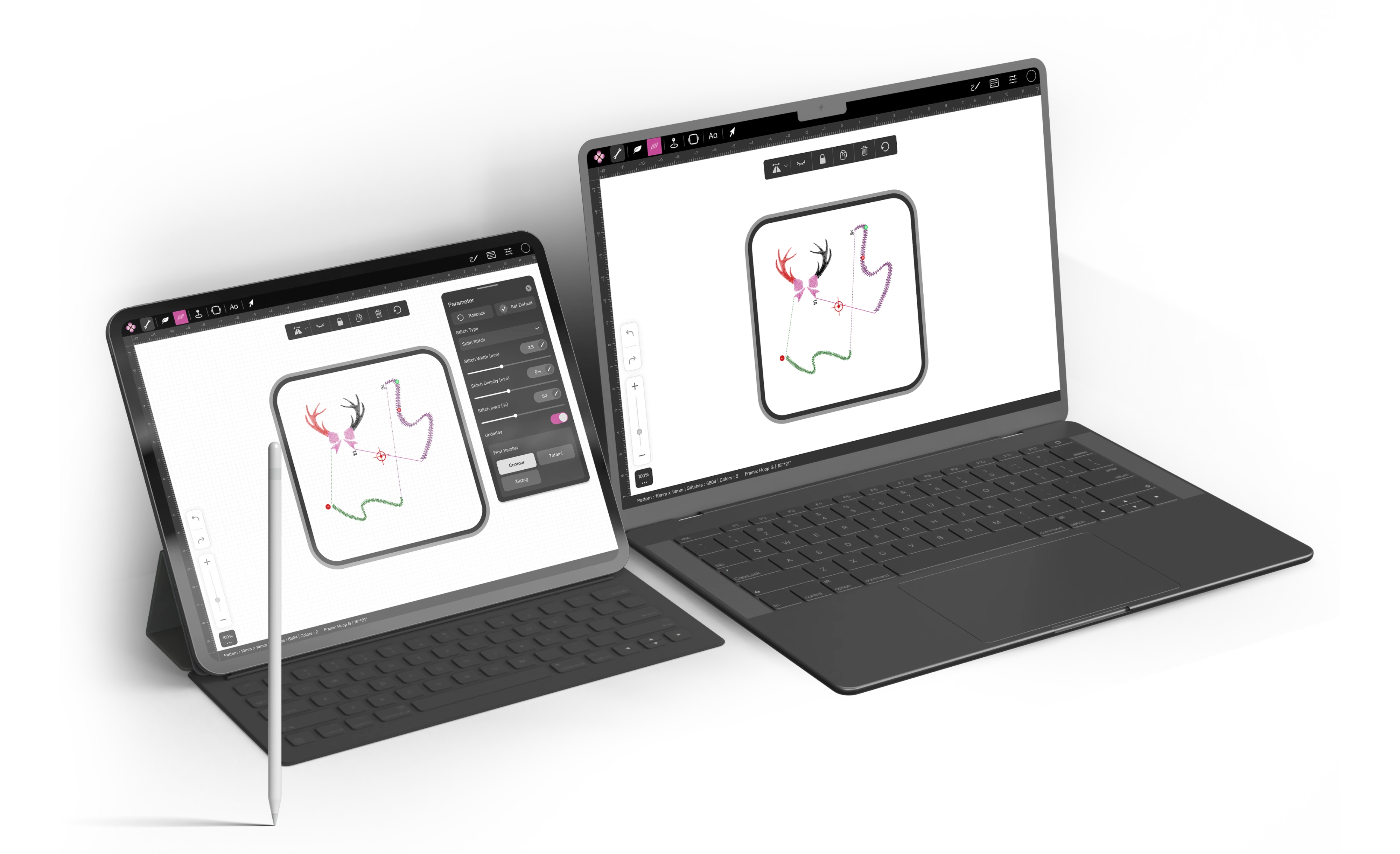

Transmission Software

Make pattern transfers more spontaneous

Embroidery Cost Calculator

Make your offer convincing

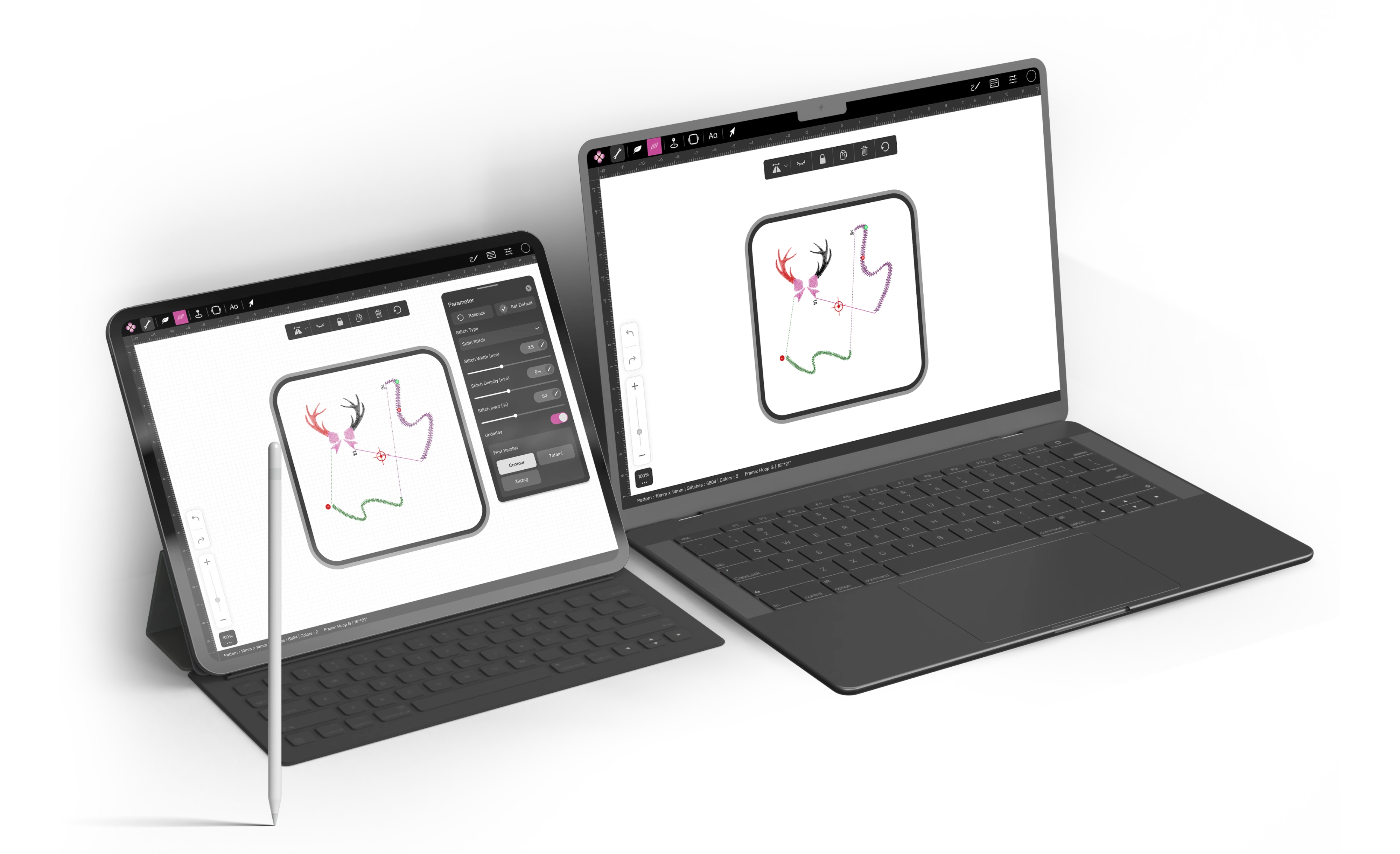

InDoodle

Inspire creativity in the cloud

Institch Doodle Digitizing Enabled

BAi's Institch R&D team has brought traditional embroidery machines to the cloud. The all-new Institch Doodle Digitizing platform is perfectly compatible with BAi machines. With one account and a laptop, you can create, operate, and manage your business anytime, anywhere—simple and enjoyable.

Transmission Software

Make pattern transfers more spontaneous

Embroidery Cost Calculator

Make your offer convincing

InDoodle

Inspire creativity in the cloud

1200spm makes production more efficient

This high speed can easily handle complex embroidery patterns or daily tasks. Dealing more orders in a short time and significantly improving work efficiency.

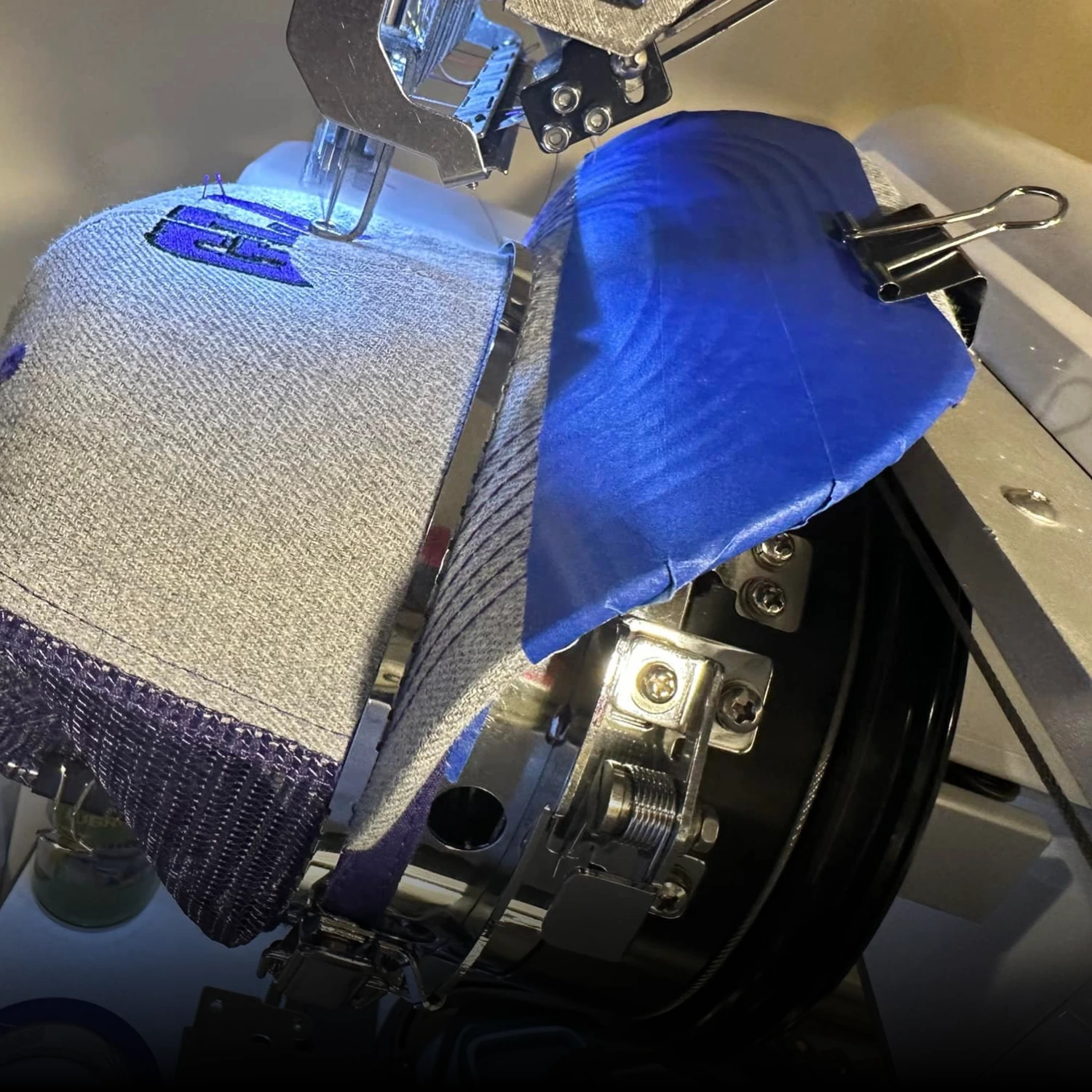

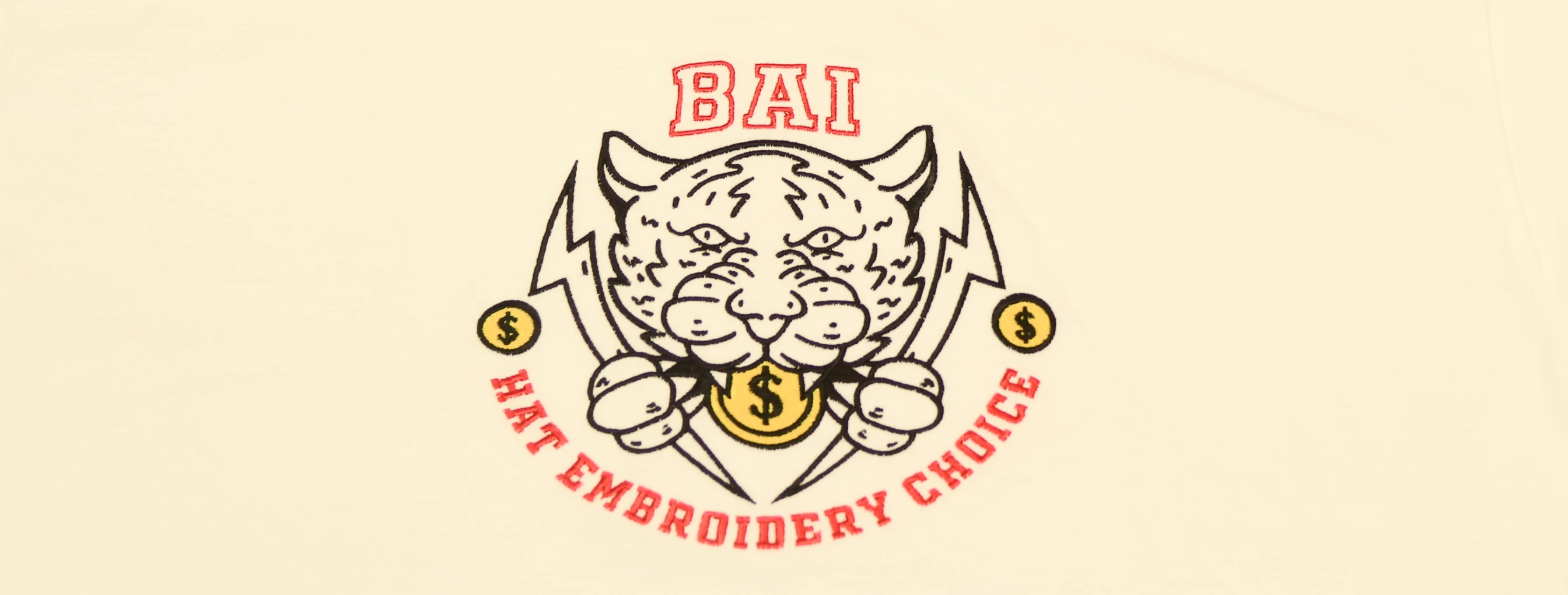

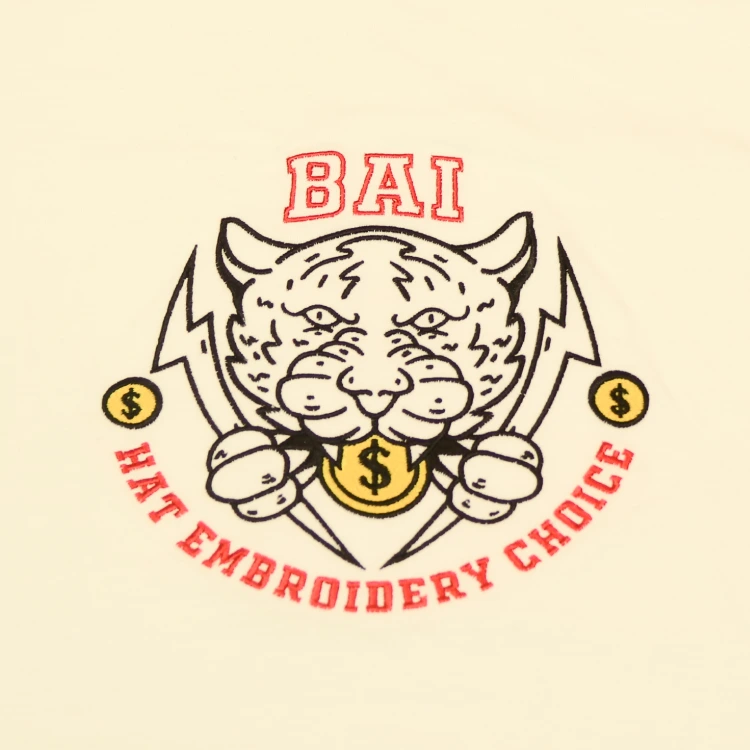

Hat embroidery choice

Solve the problem of embroidered hats with glue. The high-precision mechanical structure and electronic control panel enhance the machine's penetration and ability to handle thick materials, making the BAi embroidery machine perform better in hat embroidery. Whether it's 3D embroidery with 1-5mm puff foam or multi-layer tatami backing, it provides stable performance and high-quality embroidery. Say goodbye to bird's nest, broken needles, needle plate problems, and thread breakage.

3D Foam embroidery

Hat embroidery choice

Solve the problem of embroidered hats with glue. The high-precision mechanical structure and electronic control panel enhance the machine's penetration and ability to handle thick materials, making the BAi embroidery machine perform better in hat embroidery. Whether it's 3D embroidery with 1-5mm puff foam or multi-layer tatami backing, it provides stable performance and high-quality embroidery. Say goodbye to bird's nest, broken needles, needle plate problems, and thread breakage.

3D Foam embroidery

3D Foam embroidery

Hat embroidery choice

Solve the problem of embroidered hats with glue. The high-precision mechanical structure and electronic control panel enhance the machine's penetration and ability to handle thick materials, making the BAi embroidery machine perform better in hat embroidery. Whether it's 3D embroidery with 1-5mm puff foam or multi-layer tatami backing, it provides stable performance and high-quality embroidery. Say goodbye to bird's nest, broken needles, needle plate problems, and thread breakage.

Make embroidery quality control smarter

Although THE MIRROR is BAi's entry-level machine, it significantly improves embroidery quality through precise control of mechanical motion test data and the stable head-shaped structure. Advanced electronic control further enhances embroidery performance, with optimized algorithms and motor coordination delivering outstanding results. Additionally, the machine is upgraded with three motion curves, allowing the smart control panel to automatically select the best one for precise operation, greatly improving embroidery accuracy.

You can get a dual-head machine for $10,000+

Even with a limited budget, you can own a high-performance international brand double-head machine at an unbeatable price. BAi makes international brands accessible to everyone!

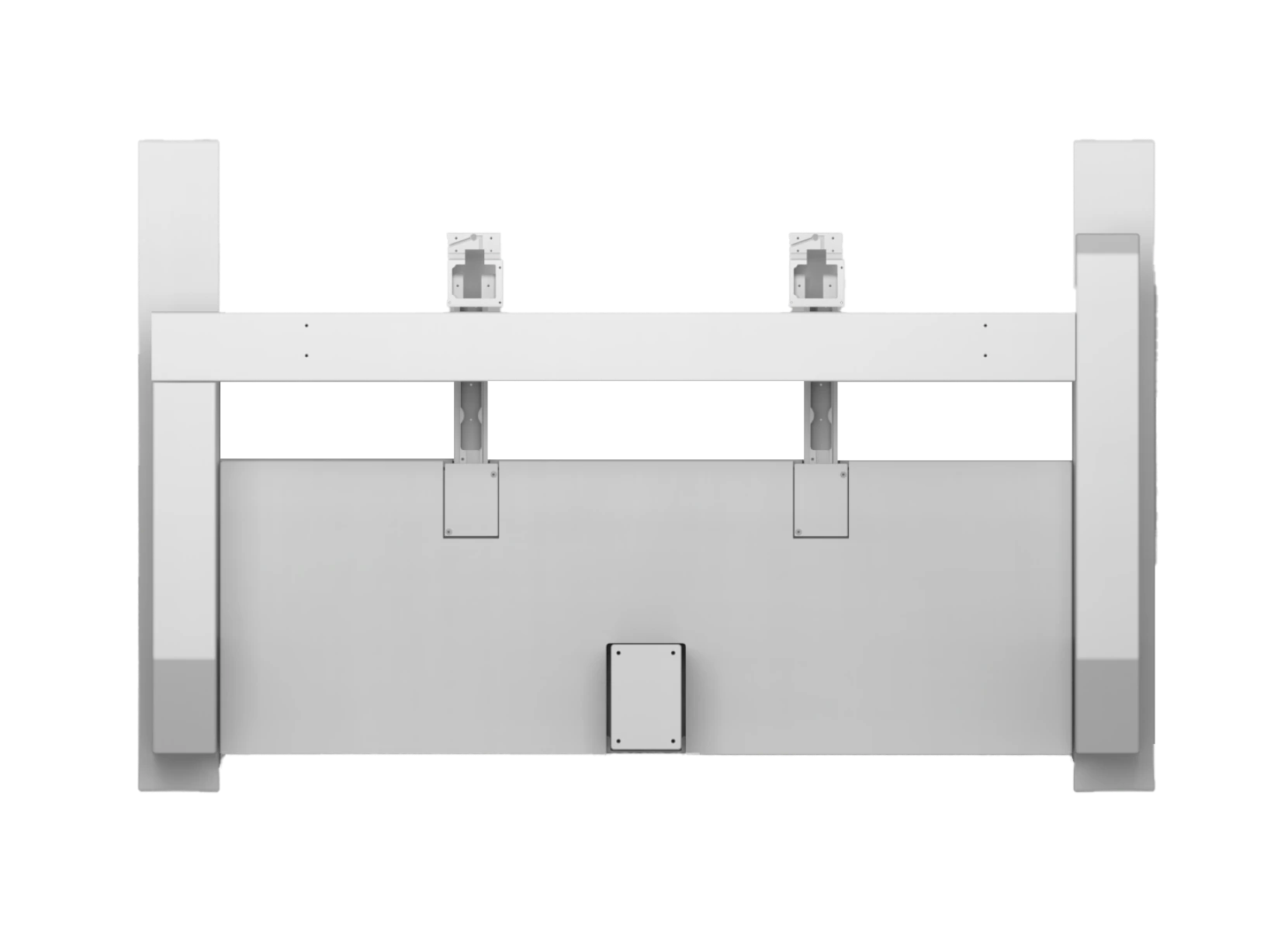

THE VISION-2HEADS

Information

Heads

2

Needles

15

Max

1200spm

Max Embroidery Area

400*500mm(15.7"*19.7")

Voltage

AC100V-240V 50/60 HZ

Packing

Wooden Case

Connection

USB & WIFI (Institch Cloud)

Control Panel

Institch OS5

Size

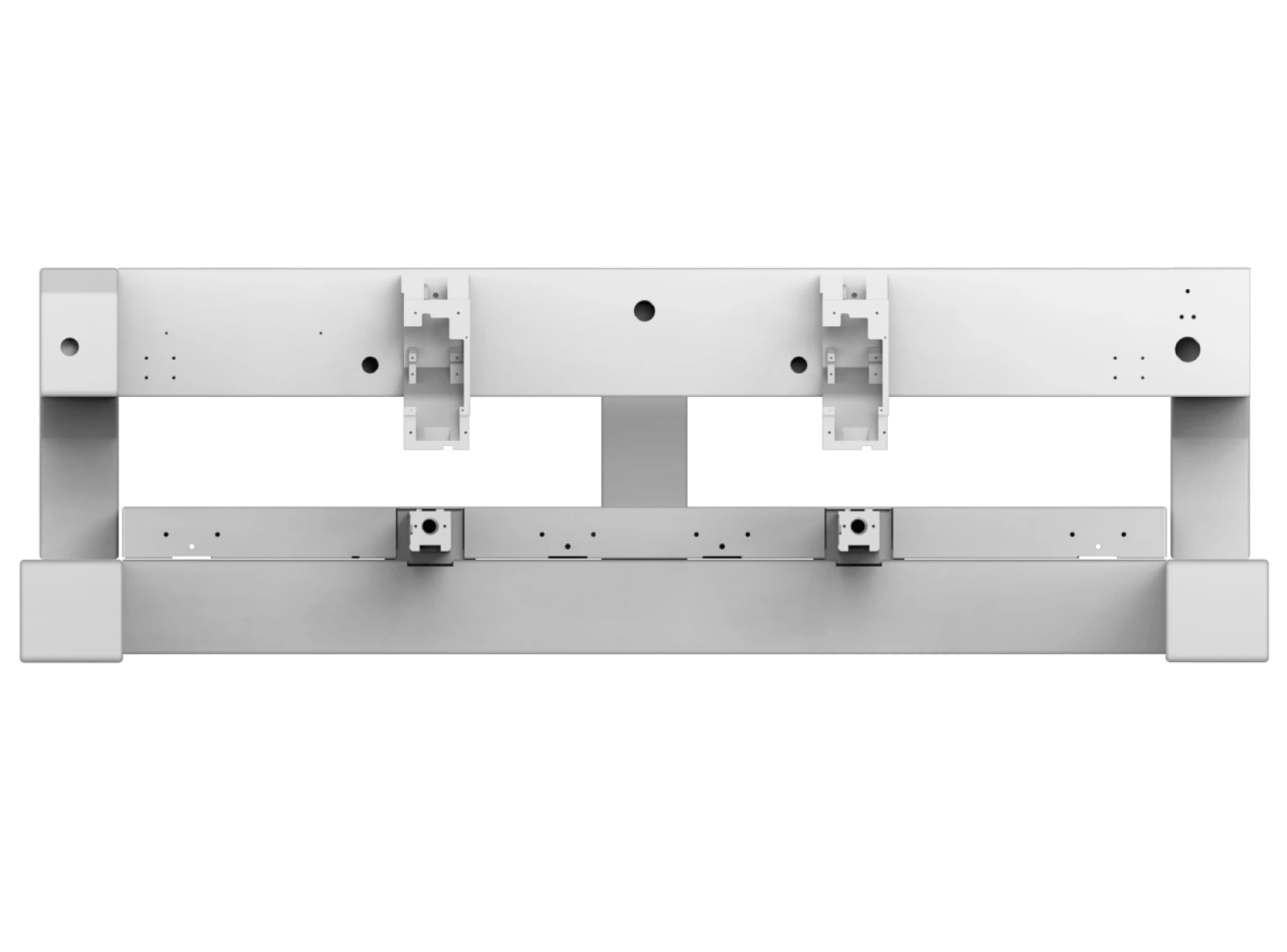

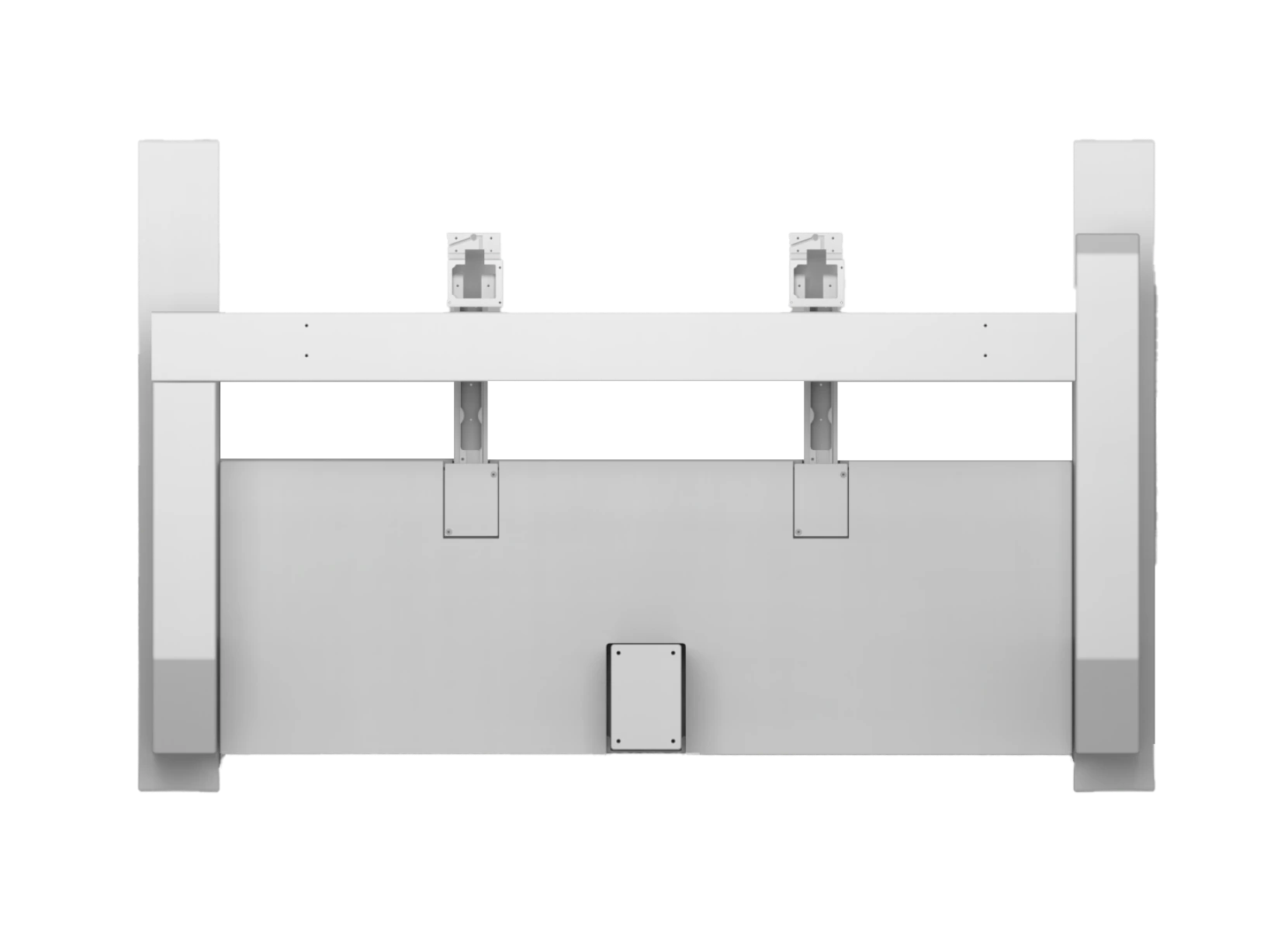

Machine Size

150*87*167cm 59.1"*34.2"*65.7"

Machine Weight

338kg/745lbs

Package Size

167*113*88cm 65.7"*44.5"*34.6"

Package Weight

430kg/948lbs

Other

Warranty Policy

We offer 1-year full machine warranty and lifetime free after-sales service

Machine Warranty: Free repairs and part replacements for defects caused by component quality. Accessory Warranty: 1-year free warranty for functional accessories; consumables are excluded. Return Guarantee: Fast returns or exchanges for quality defects within the warranty period. After-Sales Support: Free global spare parts delivery, professional online guidance, and paid on-site service in select regions. Used Machines: Lifetime free after-sales service and 1-year parts warranty (calculated from the manufacturing date).

View Full Policy Details